GIANT Series Extra-large Roller Shutters

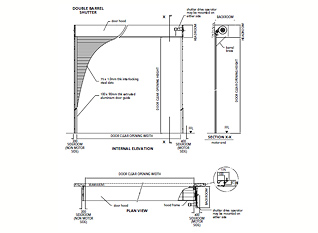

For extra-large openings exceeding a width of 12,000 mm or a height of 7,000 mm, our GIANT Series comes with a dual-barrel design that alleviates excessive deflections and enhances wind load capabilities.

Available in two types of slats:

Single-skin Slats for narrow but high doors

- Roll-formed in 1.0 mm or 1.2 mm thick galvanized steel

- Finishing - Pre-painted Colorbond (standard colors), Powder coated, or Pvf2 coated

Double-skin cavity Slats for wider doors

- 80mm x 20mm thick double-walled steel roll-formed cavity slats for greater resistance to wind pressure

- Insulation infill is optional

- Finishing - Pre-painted Colorbond (standard colors), Powder coated, or Pvf2 coated

Technical Data

Drum Assembly

The barrel assembly employs a dual-barrel system. The main barrel consists of an extremely rigid steel tube sheathed over a pair of drive shaft assemblies fitted to heavy duty bearing sets and supported at both ends by steel head plates. The drive shaft is a solid polished-steel round bar incorporating key ways to accept the drive sprocket. The head plates are 8mm thick with shafts of 50mm diameter.

The secondary barrel is located at the front of the main barrel, feeding the door curtain vertically into the guide channels. At the same time, it alleviates the horizontal deflection of the door curtain and significantly improves the wind load capability of the shutter by stiffening the top portion of the door.

Fall Arrestor

The drive shaft is fitted with a Fall Arrestor device that will immediately arrest the shaft as soon as the shaft rotates at a higher speed than normal. This is a safety feature that will eliminate the possibility of the curtain freefalling in the event of a motor failure.

Door Curtain

Material

The door curtain is made up of sturdily designed galvanized steel scroll-profiled interlocking slats, 75mm high x 1.0mm or 1.2mm thick. For wider doors, 80mm x 20mm thick double skin cavity slats are used for extra rigidity.

End Clips

Steel end clips are secured to alternate slats to prevent lateral movements. Cavity slats are fitted with profiled steel end clips at each end of every slat.

Wind-lock Clips

Steel wind-lock clips are provided at about 4-slat intervals as a standard fitting.

Bottom Rail

The bottom rail is a single length inverted 'T' double-walled extruded aluminium profile of overall 20mm thick, with the base containing a slot to retain the bottom seal.

Bottom Seal

The bottom rail is fitted with a finned PVC bottom seal that will seal against the floor when the door is fully closed. An astragal tube weather seal is available as an option where a safety edge or tighter weather sealing is required.

Safety Edge

A pneumatic bottom safety edge is available as an option. This consists of a pneumatic switch fitted to the bottom rail, connected to the astragal weather seal and wired to the motor controls. Both ends of the weather seal is capped, such that it forms an air tube. Whenever the closing door is obstructed, the astragal tube will be compressed, forcing out a tiny gust of air to activate the pneumatic switch. The switch will in turn activate the motor operator to instantly stop the downward travel of the shutter.

Door Guides

The guides shall be a heavy-duty extruded aluminium guide channel of overall size 90mm x 100 mm deep, incorporating the wind-lock feature. It has a built-in cavity to accommodate and conceal the cable chain of the safety edge system, thus eliminating the need for an exposed trailing spiral cable that may pose a safety hazard. Rubber seals are fitted to the lips of the guides to prevent metal-to-metal contact, thus ensuring a smooth and quiet operation. It also features a removable guide cover to facilitate easy maintenance.

Door Operation

Motor Drive

The drive unit consists of a suitably-sized linear drive motor operator mounted parallel to and behind the door roll. It has an integrated gearbox and a chain-operated sheave wheel for manual operation in case of power failure. The control box is lockable, housing a set of push buttons for 'Up', 'Down' and 'Stop' operations. The door travel shall automatically stop at the desired upper and lower limits via adjustable limit switches.

For shutters without a safety edge, the 'Down' button shall require the operator to push and hold when closing the shutter. This is to ensure the closing operation is being supervised. Upon sighting an obstruction, the operator will automatically release the button by reflex. This will instantly stop the downward travel of the shutter and prevent accidents.

Power supply shall be either Single Phase 230V x 15amp or a 3 Phase 415V x 20amp, depending on the size of the shutter.