Storm Shutter

High Wind Pressure-Resistant Shutter

Global climate change has seen tropical storms occurring more frequently, often with greater intensity and ferocity.

In response, we developed the GLIDEROL Storm Shutter to help protect larger door openings, and mitigate excessive damages that may be inflicted on your property by the destructive forces of powerful storms.

The GLIDEROL Storm Shutter was tested* for its capability to withstand pressures from wind speeds in excess of 200 km/h (125 mph), like those from severe storms such as Category 3 Hurricanes.

HOW ARE WE DIFFERENT

Most wind resistant shutters rely on wind-locks to help the shutter resist the wind force. This consists of a series of wind clips affixed to the edges of the shutter curtain. The clips are designed to latch onto the door guides when the shutter curtain is under wind pressure, thus preventing the shutter curtain from being dislodged from the guides. But since the guides are affixed to the door jambs for support, the resultant wind load is ultimately transferred to the door jambs.

Hence, when under wind pressure, the shutter curtain will respond by pulling against the guides, which will in turn pull against the fasteners holding it to the door jambs. As such, the ability of the shutter to resist the wind force is actually dependent on the fasteners and the substrates of the door jambs. So, if the fasteners or the door jambs fail to hold, the shutter will still succumb to the wind force despite having the wind-locks.

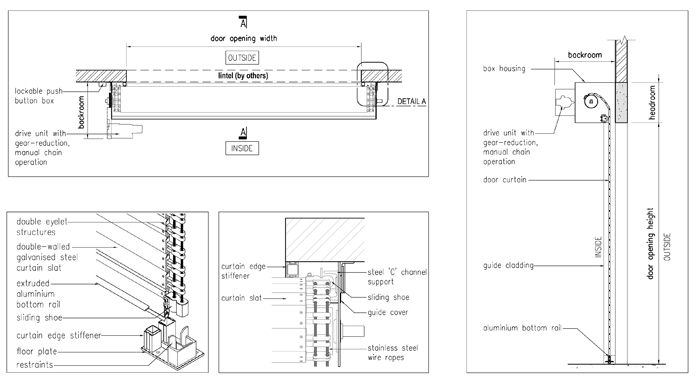

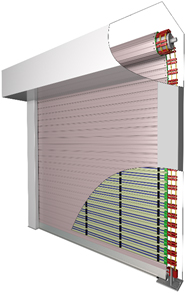

The GLIDEROL Storm Shutter relies on a horizontal lattice formation to resist the wind force. The shutter curtain is formed by double-walled cavity slats. Each slat has two horizontal steel rods in its cavity, running across the entire length of the slat. The ends of each rod are fitted with steel double eyelets. A pair of steel cables are threaded through these eyelets, linking all the eyelets vertically on each side of the curtain.

The top ends of these cables are secured to the door barrel while the bottom ends terminate securely into compression sleeves that are housed within the bottom shoes. These shoes are steel mouldings with recesses to engage the restraints that are located at the floor plates. Steel rods running through the bottom rail connects the pair of shoes to form the bottom chord of the lattice formation.

The shutter curtain is guided to travel up and down in a straight line to ensure that the bottom shoes will positively engage the restraints at the floor plate when the shutter reaches the fully-closed position. Once engaged, the entire lattice formation becomes ‘anchored’ to the floor.

Together with the cable links at both ends, the resultant effect of the above arrangement is a pliable lattice formation as illustrated above. It works like a flexible net that allows the shutter to cushion, absorb and deflect the wind forces. The symmetric curtain design ensures it is equally effective against both positive and negative wind pressures. As such, the shutter can “last all day” if buffeted by the wind in a severe storm.

With none of the guide members attached to the door jambs, the GLIDEROL Storm Shutter does not rely on the integrity of the door jambs to resist the wind load. This enables it to withstand very high wind forces regardless of the type and construction of the door jambs.

*Tested to ASTM 330E/330M up to 2.5 kPa. Test specimen size: W 6.0m x Ht 5.0m

PATENT INFORMATION:

WIPO Publication No. WO 2020-246941A1

Australia – No. 2019341063

Canada – No. 3,174,041

China – No. 2019800055611

Europe – No. 19 856 411.4

Hong Kong – No. 62021029240.0

Japan – No. 7108693

Korea – No. 10-2335678

Macao – No. J/006061

Malaysia – No. PI 2020002272

New Zealand – No. 762462

Singapore – No. 11202002050W

Taiwan – No. I71512

USA – No. US 11,187,030B2

Vietnam – No. 1-2020-06364

Technical Data

Drum Assembly

Barrel

The barrel assembly consists of an extremely rigid steel tube sheathed over a pair of drive shaft assemblies fitted to heavy duty bearing sets and supported at both ends by steel head plates. The drive shaft is a solid polished steel round bar incorporating key ways to accept the drive sprocket. Corresponding to the size of the shutter, the head plates are either 6mm or 8mm thick with shafts of either 38mm or 50mm diameter

Self-Supporting Design

The shutter incorporates its own structural support in the form of a ‘goal post’ formed by steel “C” channels. The entire drum assembly shall rest on the vertical members, with the end plates attached to the lintel for stability. The bulk of the shutter weight is thus transferred to the floor.

Door Curtain

Curtain Slats

The door curtain consists of 80mm x 20mm thick double-walled steel roll formed interlocking cavity slats. The slats are reinforced with steel rods spanning the entire length of the slat. Proprietary steel double-eyelet structures shall be attached to each end of the steel rods to receive the restraining cables.

Bottom Rail

The bottom slat is coupled to an aluminium profile base and fitted with a finned PVC weather seal. Attached to each end of the bottom slat are steel sliding ‘shoes’ that are part of the restraining mechanism. These shoes are connected to each other by steel rods spanning across the entire bottom slat.

Restraining Mechanism

A pair of stainless-steel cables are threaded through the eyes of the eyelet structures on each side of the door curtain. One end of each cable is attached to the steel tube of the barrel assembly while the other terminates into compression sleeves that are housed within the respective sliding shoes.

Vertical guide posts on each side of the door will ensure that the door travels up and down in a straight line. Upon reaching the fully-closed position, the sliding shoes will automatically engage the steel restraints on the floor plate, thus anchoring the bottom rail to the floor plate and prevent dislodgement under wind pressure.

Door Guides Cover

The removeable guide covers are fabricated from steel sheets. They are bent and shaped to cover the edges of the door curtain and secured to the vertical shutter supports.

Note: The guide covers are non-structural and serve an aesthetic purpose only.

Door Operation

Motor Drive

The drive unit consists of a suitably-sized linear drive motor operator mounted parallel to and behind the door roll. It has an integrated gearbox and a chain operated sheave wheel for manual operation in case of power failure. The control box is lockable, housing a set of push buttons for Up’, ‘Down’ and ‘Stop’ operations. The door operation shall automatically stop at the desired upper and lower limits via adjustable limit switches.

For safety reasons, the ‘DOWN’ button shall require the operator to push and hold when closing the shutter. This is to ensure the closing operation is being supervised. Upon sighting an obstruction, the operator will automatically release the push button by reflex. This action will instantly stop the downward travel of the shutter and prevent accidents.

Power supply shall be either Single Phase 230V x 15amp or 3-Phase 415V x 20amp, depending on the size of the shutter.