Gliderol Fall Arrestor

For non-counterbalanced Roller Shutters, the entire curtain weight is being held up solely by the motor operator. Consequently, should the motor operator becomes somehow decoupled from the door roll, the door curtain is free to fall by gravity. This poses a significant safety concern, especially for large shutters. The falling curtain can cause severe injury should it land on someone who happens to be under the shutter at that time. This situation can be prevented in two ways. One way is to counter balance the shutters with torsion springs so that the curtains no longer relies on the motor operator to hold it up. However, this is quite a costly solution. The other option is to fit the barrel shaft with a Safety Arrester that can stop it from turning uncontrollably.

The two common causes of falling shutter curtains are:-

- The drive chain linking the door to the motor operator breaks, slips off or becomes dislodged. This can happen if the drive sprockets are not properly aligned or if any of the sprocket shifts after a short period of operation; and

- The output shaft of the electric motor wears off and loses its ability to engage the gear box of the motor operator. As the output shaft is enclosed inside the operator housing, it cannot be visually checked. Consequently, such failures go undetected and unlike (a) above, can occur suddenly without any warning or signs.

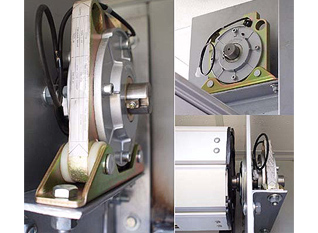

Any of these occurrences will result in the decoupling of the door from the motor operator and the door curtain is then free to fall by gravity. The Gliderol Shaft safety Arrester is designed to prevent a free-falling shutter curtain that may arise from these two causes. This device is fitted onto the barrel shaft such that its bore will rotate along with the shaft as shown below.

How it works

Construction

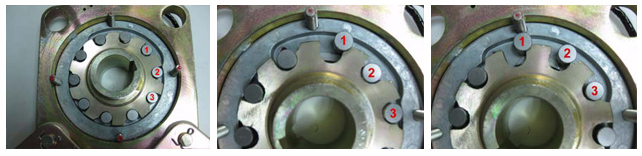

The bore is machined from a single piece of steel plate with a radial flange that is profiled as shown. The flange has 10 rounded recesses that are dimensioned to fit one solid steel cylindrical ball each. The bore and flange will rotate in a fitting groove formed by the housing. This groove has a lay-by at the top with a raised island in the middle. As the ball reaches this island, it will be guided to travel around it and then drop back into the recess by gravity after passing the island.

Normal Operation

When the bore is rotating at the normal speed, the flange will regulate the orbiting steel balls to travel along smoothly and orderly. At this speed, the steel balls will drop back into their respective recesses before reaching the edge of the lay-by. Hence, the bore's rotation is not impeded.

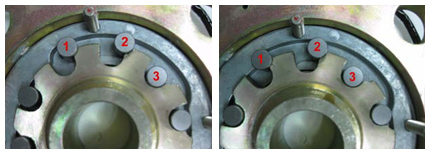

Arresting Action

Should the barrel decouple from the motor, the curtain will start to close by gravity without any restraint. This will result in the shaft rotating at an increased speed. Consequently the bore will also rotate at the increased speed. This faster rotation will result in centrifugal forces that will throw the steel balls against the outer rim of the groove. When that happens, one of the metal balls will inevitably get caught at the edge of the lay-by, thus wedging it against the flange. This action will prevent the bore from turning, thereby 'arresting' the shaft and preventing it from also turning. As a result, the door barrel will be stopped from unrolling the curtain and the closing sequence is instantly stopped.

In order to avoid any unintended stoppages, the device is calibrated to activate only if the rotation speed exceeds 22 rpm. This roughly translates to a door closing speed of about 400 mm/sec. And as these actions are triggered purely by natural forces, this device is considered to be a fail-safe mechanical device.